We take great joy in having delivered to so many satisfied customers over the years. We also take deep pride in the quality, craftsmanship and the rapid turn-around time of the parts and components we produce. And we accomplish both these outcomes by paying great attention to detail even before you got in touch! Our proven quality, precision and fast turn-around is built around three core foundations:

- Exceptionally High Quality Machines and Tools

- Deep Integration of In-Process Metrology

- Real-time Monitoring and Remote Access

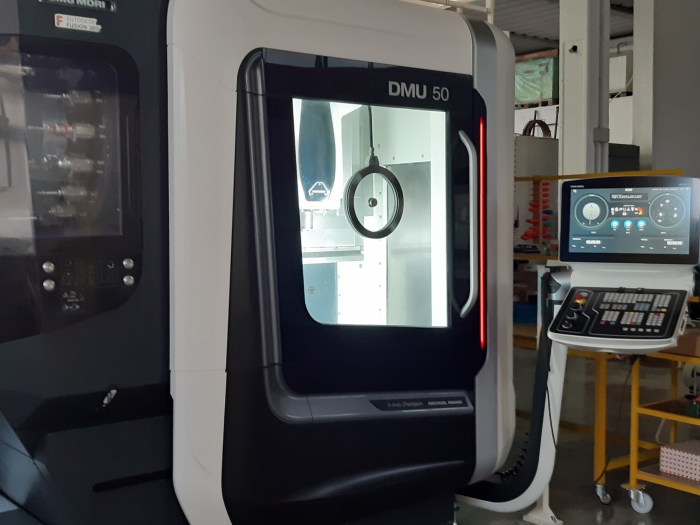

MACHINES

We use Swiss, German and Swedish tools, tool holders. And DMG MORI continuous 5 axis CNC machines.

For CAD and CAM programming we use best in class Siemens PLM and Autodesk software.

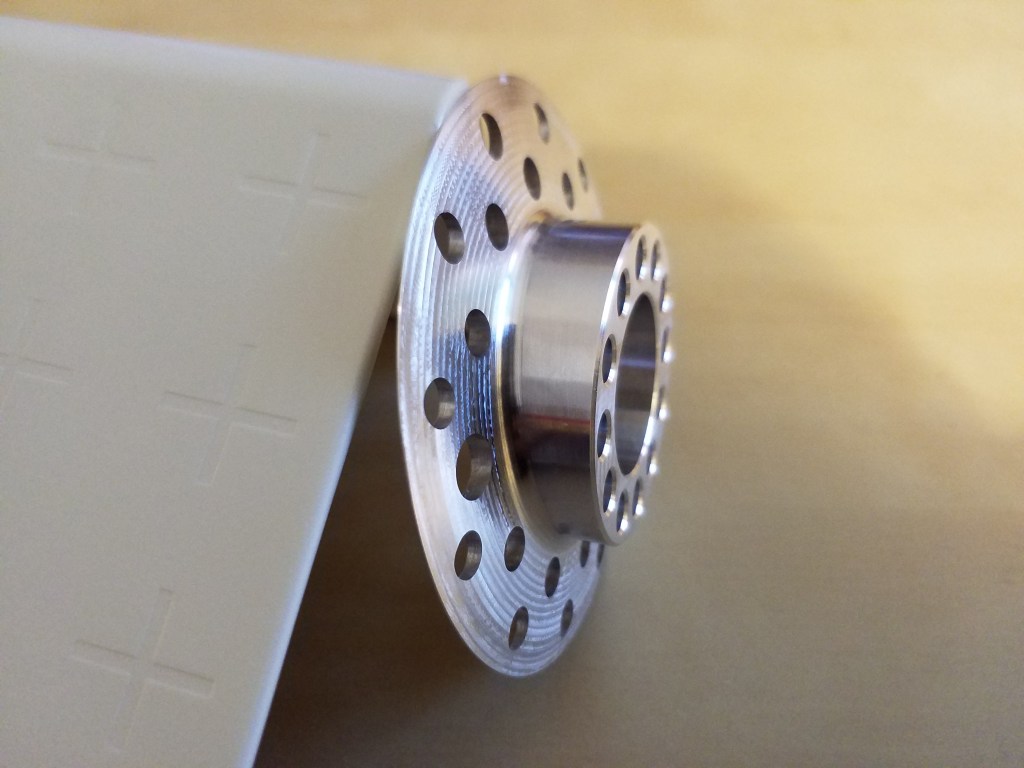

TOLERANCES & LIMITS

We can machine metal parts to sizes as large as 1000mm x 600mm x 400mm.

We achieve consistent dimensional tolerances within ±7 microns or 0.000275″ and ±2microns on holes.

Materials

We can supply machined and fully finished parts in a wide range of metals and alloys . These include:

Ti6Al4V, Al alloys 7075, 2017, 2024 etc.

Superalloys

Carbon composites

XPDYT – Building Blocks of ‘XCPTIONAL’ Precision and ‘XCPTIONAL’ Quality

Our tolerances and precision are second to none and production status is transparent to you by special secure access to our ERP system. Our ERP system is designed to trace and trace every bit of information that we produce and you have the benefit of auditing it during or after the production process.

Here’s more about why XPDYT is for you – and if you get to the end we promise to tell you why we truly are an extension of your production and business operations.

XPDYT is a boutique metal machining and composites manufacturing service from Nashero for low rate and series production of medical, military and aerospace components.

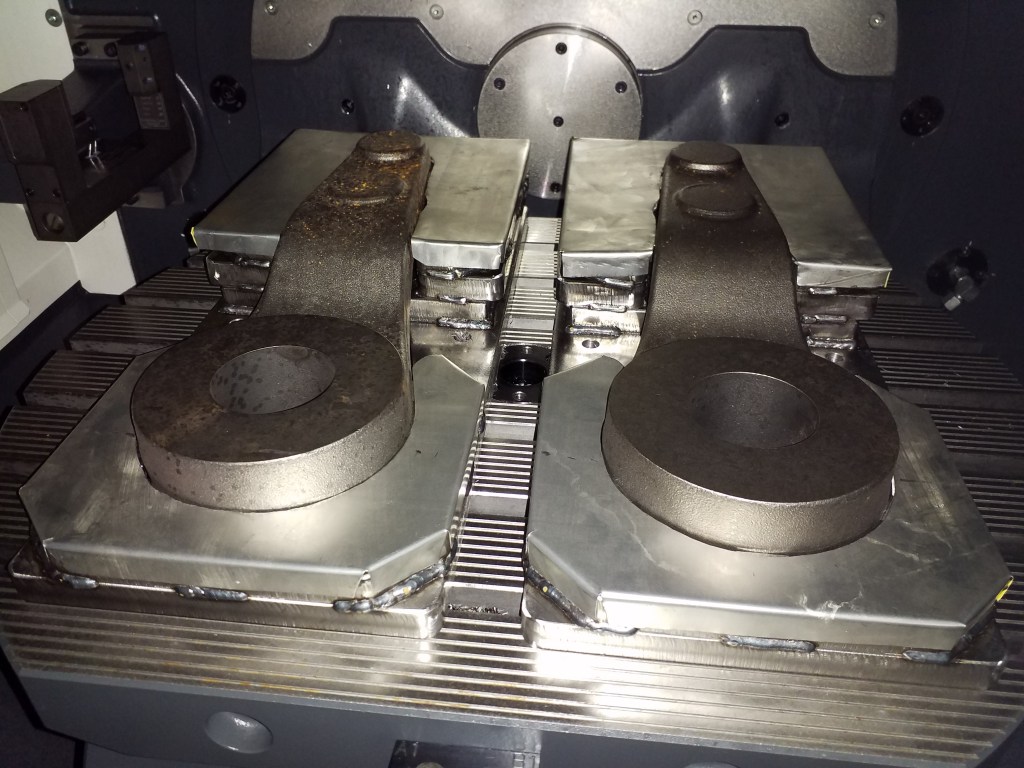

Larger Machines Means Faster Turn-Around and Shorter Lead Times

Most comparable machining shops use smaller machines than Nashero does. Our large size DMG Mori machines are capable of making multiple part sets in one go.

This lowers the turn around time and which means lead times for ordering parts from us are far less than others. It also means we are able to produce more parts with the same team than other shops.

Machines with larger beds also mean less loading and unloading and thereby less variance across part sets.

Swiss Made Tools and Tool Holders

During precision machining it is also essential that the entire process and factors that enhance precision should be of a very high quality. Therefore, for the tight tolerances we work with we we also use the finest tools from the best tool suppliers in the world, and the most accurate tooling and tool holders, mainly Swiss made. This also significantly reduces down-time and loss of product due to tool breakage.

In-process Metrology

Normally what happens is CMM (computer aided metrology) is after a part is machined it is dismounted and measured separately. With XPDYT‘s in-process metrology there is no shift to the measurement room. We have in-machine probing so when part is being machined, it is also being measured. And when the machining is done the part has already been measured for spec in-process. This not only reduces wastage but there is no need for the part to be resent into the machine if the measurement is off-spec.

In-process Hygiene – Aerospace Practices!

Most companies do not clean bores and apertures – in aerospace we have to. We have copper tubes – to go inside and clear debris. Unique to aerospace. If we have to do multiple operations – roughing, semi-finishing, finishing – debris that is left from the roughing or semi-finishing operation. cutting environment has to be pristine. Also done during probing.

Our Certifications

XPDYT and parent company Nashero S.R.L have received and are in-process of receiving various certifications. More details are available here.

Industry 4.0 Setup with Real-time monitoring

We program our 5 axis, 4 axis and 3 axis machines offline and using our Industry 4.0 setup, we can immediately load the machines using our production network which seamlessly connects to all the machines and enables us to monitor machine status 24/7.

Our integrated in-process CMM machine also measures and transmits readings in real-time to the manufacturing system. And our integrated laser machine can mark serial numbers in-process for correlating to data.

Remote Access and Real-time Monitoring

Your supply chain team will have access to resource availability and delivery schedule based on our work status. On your requirement, we can also keep a few machines tooled up and ready for only your jobs. These will not be used for any other customer.

In fact because we have shorter lead times, real-time visibility, ability to track and load data to your systems consider us an extension of you current production arm. With our on-site ability to pre-positioned source-traced raw materials we can provide on-demand burst capacity for your most urgent needs.

LET’S BUILD SOMETHING TOGETHER.