“If you need repeatable tight tolerances and high surface finish on complex parts – we are the team for you!” – Dr. Naresh Sharma

XPDYT makes complex metal and composite components for the aerospace, defense and medical instruments industries. If you are looking for a reliable supplier for your machining needs, we look forward to hearing from you. We have worked extensively with customers from aerospace, defense, race car and other industries, whose tolerances and quality was easily met by our rock solid processes and machine tools.

We take great joy in having delivered to so many satisfied customers over the years. We also take deep pride in the quality, craftsmanship and the rapid turn-around time of the parts and components we produce. And we accomplish both these outcomes by paying great attention to detail even before you got in touch! Our proven quality, precision and fast turn-around is built around three core foundations:

- Exceptionally High Quality Machines and Tools

- Deep Integration of In-Process Metrology

- Real-time Monitoring and Remote Access

MiliTARY

We are a proven mil-grade manufacturer for low-rate and series production and have delivered parts and subassemblies to EU and US primes. Our capabilities cover sea, air, land and space vehicles as well as the individual combatant.

AEROSPACE

We have a special purpose practice to support aerospace prototyping, R&D and experimental development including advanced components for Civil Aviation (fixed and rotary), Urban Air Mobility (UAM) and heavy-lift Drone components.

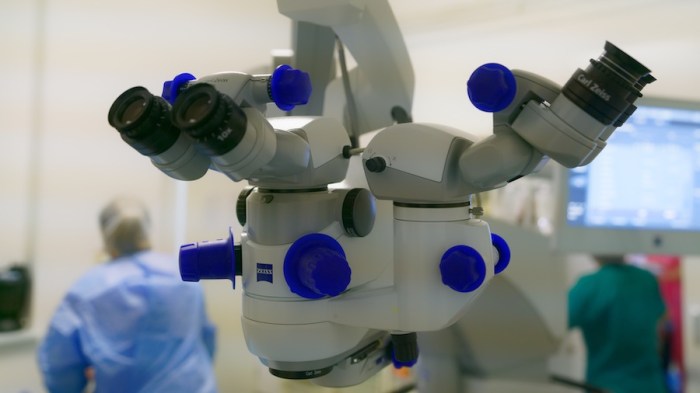

MEDICAL

Whether it is saving a life or discovering a life-saving drug critical research learn more about how XPDYT brings cutting edge military and aerospace knowhow to medical instrument manufacturing includes full traceability.

XPDYT is a boutique metal machining and composites manufacturing service from Nashero for low rate and series production of medical, military and aerospace components.

MACHINES

We use Swiss, German and Swedish tools, tool holders. And DMG MORI continuous 5 axis CNC machines.

For CAD and CAM programming we use best in class Siemens PLM and Autodesk software.

TOLERANCES & LIMITS

We can machine metal parts to sizes as large as 1000mm x 600mm x 400mm.

We achieve consistent dimensional tolerances within ±7 microns or 0.000275″ and ±2microns on holes.

Materials

We can supply machined and fully finished parts in a wide range of metals and alloys . These include:

Ti6Al4V, Al alloys 7075, 2017, 2024 etc.

Superalloys

Carbon composites

LET’S BUILD SOMETHING TOGETHER.