Learn More About Our Tools and Setup here >>>

DMG MORI DMU 50 Generation 3 high speed 5 axis machine

New 5 axis continuous, Siemens 840DSL (Controller)

60 tools tools carrier

Preconfigured for automation

Digital scales on each axis

In machine laser tool presetter

In machine component probing

Through spindle coolant

Through spindle air

X650, Y520, Z75 with a 650mm dia table

Capability to hold 300kgs on the 5 axis table

DMG MORI Advanced Technology Cycles (ATC) for high end surfaces

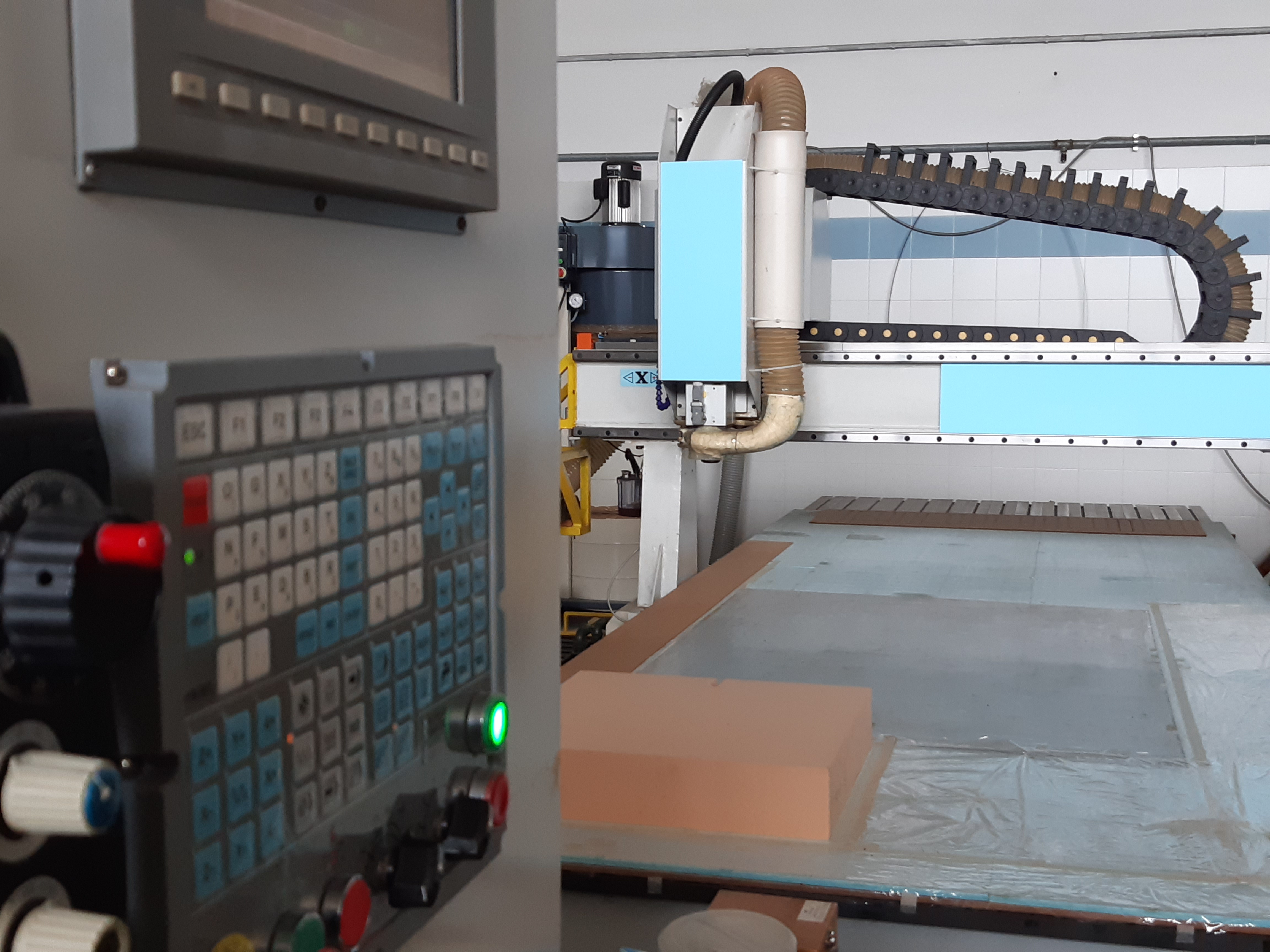

Large capacity and precise 4 axis composites machining router

X1500, Y4500, Z500mm of table.

This router has been optically calibrated in its working envelope to reduce significantly any positional errors throughout the working envelope using software.

High powered vacuum table with 8 programmable vacuum zones

Powerful vacuum swarf extraction system to efficiently remove carbon and glass fiber swarf.

DMG MORI DMC103V

3 axis with Siemens 840D control networked with the ERP system.

X1000, Y600, Z450

Capability to hold 800kgs on the table

This machine has a special attachment to generate and cool the tooltip with refrigerated high pressure air. The refrigeration of air is in-process. This is specially designed to cut steel and superalloys and increases precision and surface finish.

COMPUTER CONTROLLED OVEN

Main computer-controlled oven. Large dimensions – 2.5m (8.2′) x 2.5m (8.2′)x 8.5m (27.8′) in volume. Temperatures up to 200 C.

LET’S BUILD SOMETHING TOGETHER.