Learn more about our Capabilities here >>>

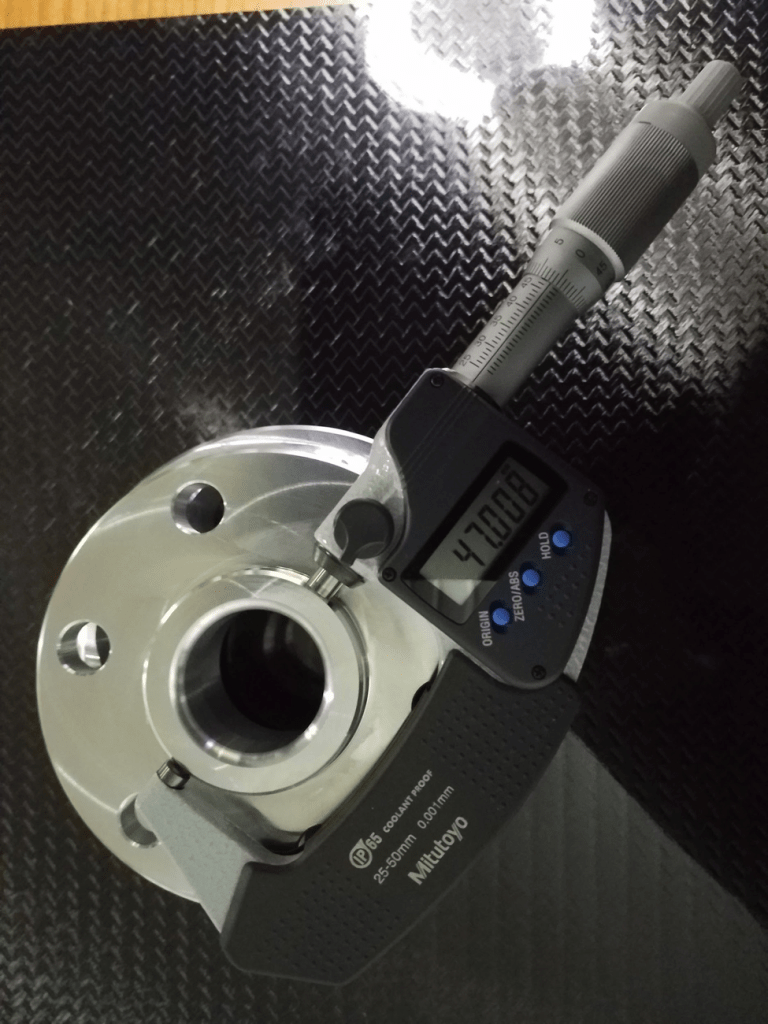

UNMATCHED TOLERANCE

Our immaculately well thought out processes deliver tolerances that are second to none as can be seen in the 0.000/+0.015 mm tolerance allowance in the photo above where we stand at the center of the tolerance band at +0.008mm.

CLEANLINESS

Our machines and the facility are kept well maintained and spotlessly clean after every work shift. We believe that cleanliness is paramount to delivering quality

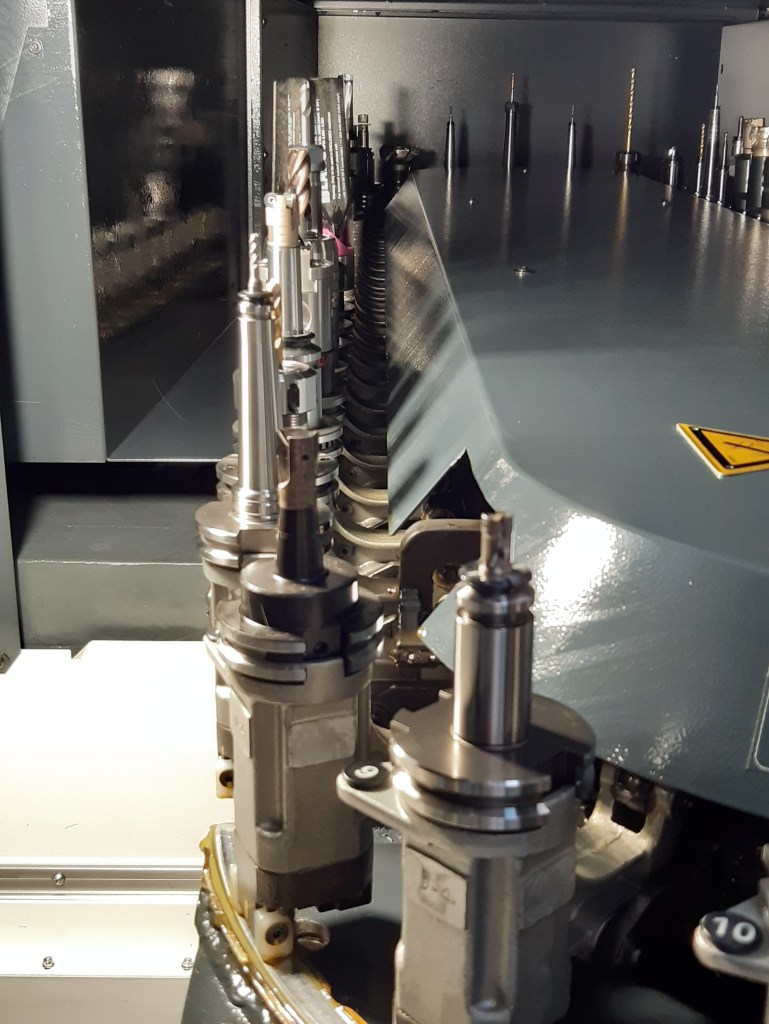

IN–MACHINE PART PROBING TOOL

This is our in machine part probing tool. This tool probe has sub-micron accuracy. It is used to estimate and “walk the tolerances,” all within the machining process so that the machine does not need to stop. This guarantees that customers get consistently perfect parts.

IN–MACHINE LASER TOOL PRE-SETTER

This is our in-machine laser tool presetter, this is capable of measuring the size and shape of cutting tools, giving unprecedented accuracy to the system.

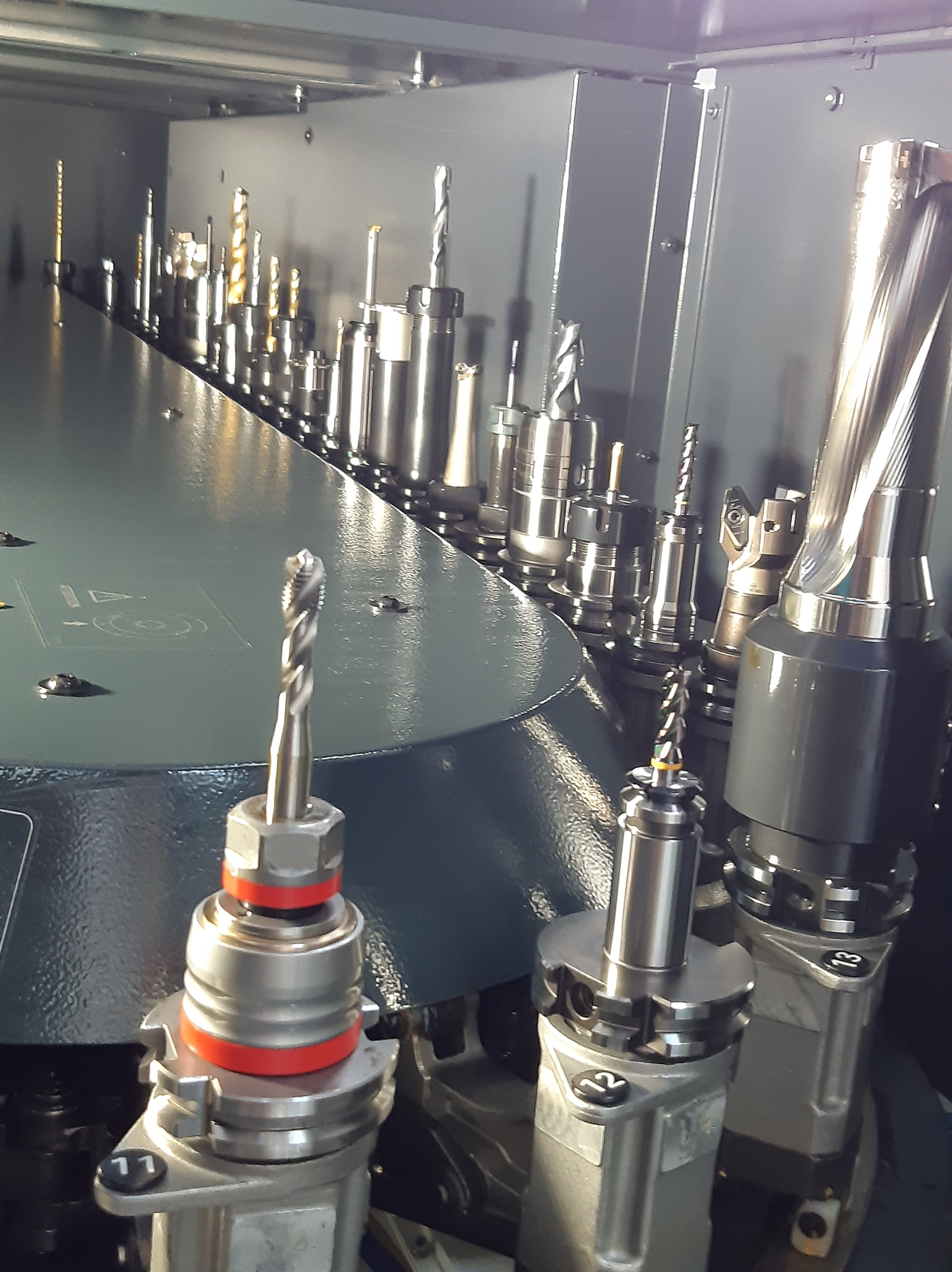

QUALITY TOOLS AND TOOL HOLDERS

A fully loaded tool carousel with all high end tool holders and tools. To deliver precision, every element counts and nothing counts more than the tools and tool holders that are the business end of machining. Using a high end machine with low end tool holders and tools is the same as driving in a supercar powered by a punny corolla engine.

We use Swiss tool setting system with special holders and collets that give extremely low runout. We also use indexable tools for high material removal rates to expedite the roughing process without wasting time. The high-end semi finishing, finishing and sometimes super-finishing tools are then used for getting into tolerances and great finishes for your parts.

LET’S BUILD SOMETHING TOGETHER.